American Blast Systems Vehicle Armor Panels

American Blast Systems Vehicle Armor Panels

Product Details:

*Level III Rifle and Handgun Protection

*2 lbs/sq ft (aprox. weight added to door = 20 lbs)

*0.5 inch thick material

*NIJ Level III tested material

*15-year warranty

*When car door is open = full shield

THE HISTORY

Keeping our agents, military and officers safe in the event of an emergency is our highest priority. Considering first-hand experiences as well as concerns from the agencies and departments, we tried every variation of armor plating and ceramic tiling possible, testing each method, and seeing the plethora of weaknesses in the current market brought us to search for the lightest and best material currently available to the DOD and law enforcement.

American Blast Systems is world renowned for our proprietary, ultra-light weight NIJ certified armor and for this program specifically we have chosen to go with our level III armor weighing in at an industry record of only 2 pounds per square foot. ABS is currently a trusted supplier that already services thousands of agencies and departments around the world. This is finally a proper solution for all motor pool vehicles to have a true ballistic shield with nearly 90% coverage throughout the entire doors of the vehicles.

WHY ABS?

Most manufacturers use outdated techniques such as simple glued on ceramic panels or small heavy ballistic plates where the size is limited to what can pass through the window slit opening that give barely a 30% coverage on the door minimizing agent safety and diminishing their confidence and peace of mind of their own wellbeing. These ceramic panels get weak and brittle over time and can break and fall into the doors. We have seen this in the multiple manufacturer recalls for different agency vehicles over the past several years. This means weeks if not months of downtime on the vehicles while waiting for warranty or service work. We also need to take into account the 50-90 pounds of additional weight on each door due to the materials chosen and after a few years of use, just the sheer weight can cause fatigue on the hinges and make opening and closing the doors difficult. This also creates an ingress/egress issue for our smaller framed officers and agents while simply parked on inclines.

THE PROCESS

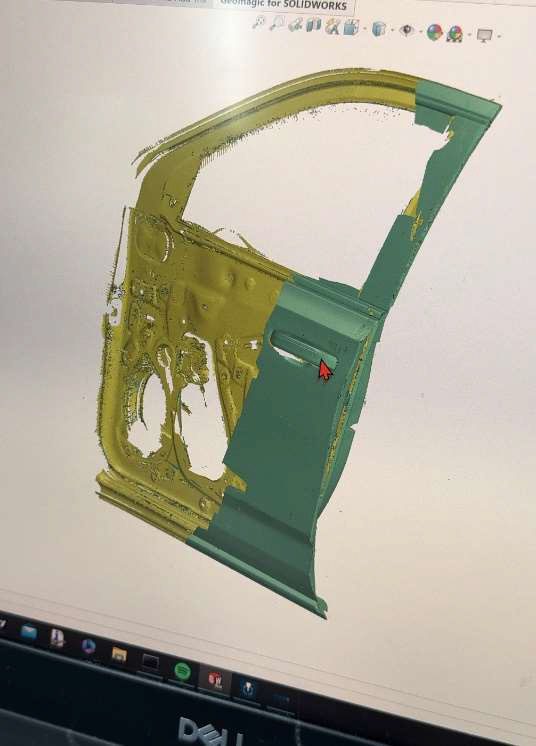

Our process is unlike any other method currently available. For every new make and model offered, we source the vehicle locally and FARO scan both sides of the door using the newest 3D modeling software with blue-laser technology which allows us to maximize all areas of the door to give us the MOST coverage over any company.

Motor pool technicians remove the entire door and tag the VIN for each pair. We send out fully enclosed, reinforced shipping crates that can safely transport four pairs of doors at a time. This significantly reduces transportation costs of sending entire vehicles anywhere and also minimizes potential damage to the vehicles themselves during transport. Upon arrival, each set of doors is set into our specialized rolling fixtures that allow the doors to be moved into our different stations.

Certified technicians remove all the door cards, plastics, wiring, glass and internal structures that would block the oversized armor panels. Our technicians have decades of experience and can easily disassemble a brand-new Ferrari F8 Tributo door (as seen here) just as easily as a Yukon or Ford Explorer.

Our 3D scanned and water jet fitted armor plates unique to each chassis are then laid into the opening of the door and bonded into the inner door skin. Unlike the competition that uses thin brackets and simple sheet metal screws that become loose over time and can fall out, our armor is actually resting on the lower sill seam so there’s never a concern that the armor will fall off or the bonding agent to give out from the weight from the countless opening and closing of the doors during the life cycle of the vehicles.

Our final build station is where any portions of the doors are reassembled and welded by our certified journeymen welders use the newest and best aluminum welders by Miller Welders before they are fully reassembled and removed from the fixtures to be placed back by VIN in the exchange shipping crates.

| CALL FOR PRICING |

Share